Injection Molding - Undercuts (How to Avoid and Design)

Description

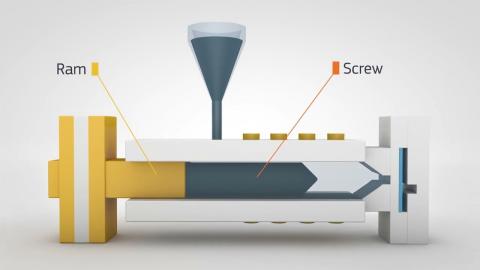

Learn what an undercut in injection molding is and how to design your part avoiding undercuts. We'll demonstrate how to re-design a part with an undercut in Fusion 360 using a shutoff.

00:00 Intro

00:23 Learn what an undercut in injection molding is. We'll demonstrate how an undercut makes it difficult for a part to be ejected from the mold.

00:50 We'll discuss the 4 main ways to avoid an undercut in injection molding.

01:01 Shutoffs explained. You'll learn how removing material under the undercut can help the part eject better from the mold.

01:26 Moving the parting line explained. This is the easiest way to avoid an undercut in injection molding.

01:42 Bumpoffs explained. Learn when and how to use a bumpoff for undercuts.

02:16 Sliding side-actions and cores explained. Learn to use side-actions when an undercut can't be avoided.

02:47 We'll remodel a part with a snap-fit feature and undercut in Fusion 360. You'll learn how to create a shutoff by making a cut out under the snap-fit feature. Finally, we'll add a draft angle to the design.

FREE injection molding manufacturing and design guide: http://3dhu.bs/zeBYlu

Instant free quote: http://3dhu.bs/BXwpfW

Subscribe to our channel for more engineering content!

3D Hubs is an online manufacturing platform that provides engineers with on-demand access to a global network of manufacturing partners. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Or get an instant quote? http://3dhu.bs/CNIk59

Facebook: http://3dhu.bs/R-OXDm

Instagram: http://3dhu.bs/7EZ5mG

Twitter: http://3dhu.bs/oRC1uy

LinkedIn: http://3dhu.bs/t2KEyM