How to Make a Built-In Entertainment Center

Description

We rebuilt some outdated shelving to make a custom built-in entertainment center. This project was sponsored by LG. LG CineBeam : http://bit.ly/2NOzisQ LG CineBeam on Amazon: https://geni.us/ZAcqaHy

Subscribe to my channel: http://bit.ly/1k8msFr

Second Channel: http://bit.ly/iltms-2

MORE PROJECTS, POSTS AND EVENTS

http://www.iliketomakestuff.com

FIND EVERYTHING WE USED IN THE PROJECT:

https://kit.com/iliketomakestuff/built-in-entertainment-center

https://kit.com/iliketomakestuff/my-woodworking-tools

https://kit.com/iliketomakestuff/shop-safety-gear

I WROTE A BOOK!!

http://www.iliketomakestuff.com/makingtime

Want to support ILTMS? Get exclusive content and more...

http://www.iliketomakestuff.com/patreon

BUY A SHIRT, STICKER, NOTEBOOK, DIGITAL PLANS and MORE!!

http://www.iliketomakestuff.com/store

FOLLOW:

http://twitter.com/iliketomakestuf

http://www.twitch.tv/iliketomakestuff

http://instagram.com/iliketomakestuff

http://facebook.com/iltms

MUSIC: http://share.epidemicsound.com/iltms

Like most of our house, this feature was built around the super-advanced technology available in 1983. When we moved in, the shelves were too low to fit my flat tv, so I had to crudely knock out some space. The initial construction was also pretty dated, with routed face frames and thin, inset doors that needed to be rebuilt.

I got out some hammers and ripped out the old pieces so that I could get an accurate layout of the space. Once I got the dimensions of the empty area, Josh made a 3d model of the new entertainment center. We took this model and made a materials and cut list and got to work.

One mistake I see beginning DIYers make is that they try to make a piece of furniture inside an existing space. Meaning, they build a piece that should be square and plumb inside a space that is neither of those things. So, for this project, we are going to build everything in sections in the workshop and assemble them together in the empty space. This drop-in technique may leave spaces on the outsides of your pieces, but those can be covered up by trim or caulking.

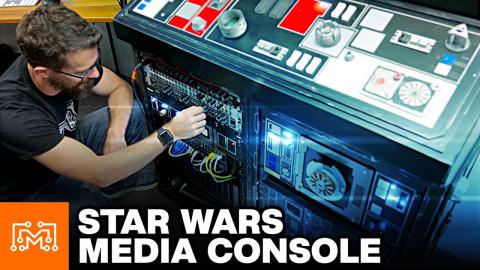

Josh modeled the lower cabinets to fit a special project that LG sent me. Our plan is to store the projector in the cabinets and bring it out when watching a movie on the big screen. The rest of the cabinets will have a shelf or will hold our gaming systems. Josh modeled the doors to accommodate frameless, soft-close concealed hinges. If you are making new cabinet doors, make sure you plan the sizes based on the type of hinges you plan on using. We use a concealed-hinge jig to drill all of the holes for the hinges that we'll attach later.

On top of the cabinets there will be a long counter top made of two shorter pieces. On top of the counter there will be two separate sections of shelving; the "adjustable" and the "TV" sections. We made these two towers independent so we could maximize our plywood usage and to make it easier to move up the stairs to the living room.

The "adjustable" section is made of three uprights joined by a top with 6 floating shelves within. The uprights were drilled using a shelf-pin jig so that we could move the two columns of three shelves around to fit different size books or pictures. The "TV" section will have a longer area to house our TV and sound bar and a separate shelf above it for nick knacks. There is another piece behind the TV that will hide any wires that area hung behind it. The two sections will be screwed together and secured to the insides of the walls.

I used a paint sprayer to cover all of the sections in some primer and white paint. Once dried, we screwed the cabinets together and filled the gaps on the sides with thin plywood strips. We set the taller structures onto the counter top and secured them together and into the walls. Now that the casework is firmly in place, I cut some pine 1x4s into 1-1/2" face frame strips.

I purchased a retractable screen with a remote on Amazon that matched the opening perfectly. Thy are available in different lengths so you can chose the right one for your space. To mount it, I added a long strip of wood to the top of the built-ins so that the screen could be hidden away behind a piece of the existing wall. I ran the power cable behind the TV area along with the rest of the hidden cables and plugged everything in to an existing power outlet.

When fully extended, the screen stops 1/4" above the counter top, it was perfect! The remote works great even though the screen is slightly hidden away. The whole unit can go from display shelves to cinematic movie screen in about 30 seconds, it's so cool. When we want to watch a big move, I can pull the new projector out of its cabinet and set it on the floor. It boots up quickly and the beautiful picture is perfectly displayed on the screen. When we're done, just put the projector away and the screen retracts up into its hiding place with the push of a button.