Avoiding Quality Problems in Manufacturing (Engineer vs Manufacturer)

Description

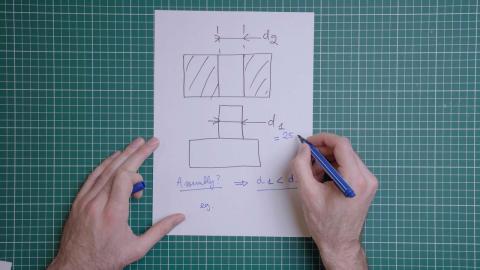

Learn how to minimize communication errors between engineer and manufacturer, causing most of the quality issues in manufacturing. We’ll teach you what requirements you need to add to your design in order for the manufacturer to know how to correctly manufacture your parts.

First, we’ll go over what we talk about in this video about quality and manufacturing.

Second, we’ll start by explaining why an engineer and manufacturer have different definitions of quality and why it’s, therefore, important that they know how to align. Functional requirements and manufacturing specifications in relation to each other are explained.

Third, we’ll go into why DfM (design for manufacturing) is so important to set up the manufacturer for success.

Fourth, We’ll discuss standard specifications. Learn why using standard specifications is a handy way to ensure quality parts.

Finally, context in manufacturing is discussed. Often overlooked but super important. You’ll learn how context plays a role in solving a conflict between DfM and standard specifications.

Website: http://3dhu.bs/6dfmkE

Get instant quote: http://3dhu.bs/UNan19

3D Hubs is an online manufacturing platform that provides engineers with on-demand access to a global network of manufacturing partners. Users can easily upload their design, instantly receive a quote, and start production at the click of a button.

Facebook: http://3dhu.bs/R-OXDm

Instagram: http://3dhu.bs/7EZ5mG

Twitter: http://3dhu.bs/oRC1uy

LinkedIn: http://3dhu.bs/t2KEyM