3D Printing Unpeeled: FMAP, Water Filters and PVDF

Description

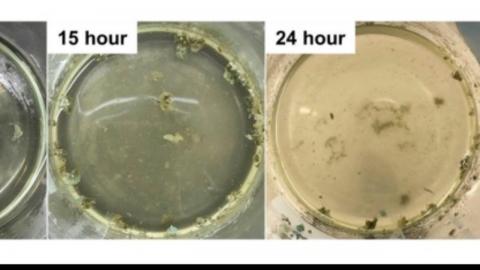

Filsa Water hopes to use PLA printed filter housing to make low cost water filters that use bottles as containers. They say they can increase the pH of the water and reduce impurities by 70%, while eliminating 90% of heavy metals. The filter caps will join two bottles and weigh just 24 grams. Quite incredibly the company says that the caps could filter 300,000 liters of water during two months.

Italy based Xenia Materials has created CFRP PVDF pellets for fused granulate fabrication (FGF) printers with increased chemical resistance and high performance. Not a lot of materials are being compounded or made specifically for FGF. More should be since reduction in warp or post processing time would make the technology significantly more viable.

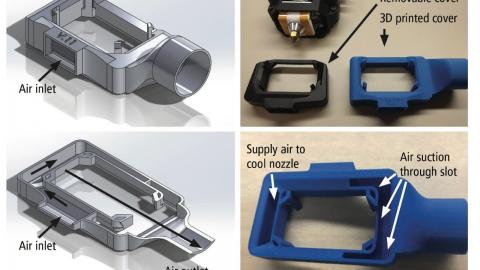

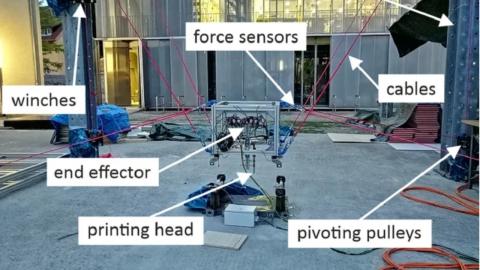

A team has integrated a single build head with FDM, direct ink writing (DIW) and freeform laser induction (FLI). This lets them extrude and functionalize a wide range of materials and properties. They call the combined process FMAP (freeform multimaterial assembly process). They build this on a Creality CR 10 which means it should be easy to replicate and work on their research and cheap to industrialize this. So far they've made a strain and UV sensors, encoders and capacitive sensors with the approach