3D Printing News Unpeeled: Schaeffler and Panasonic 3D Printer

Description

La Máquina is working with the material pure.tech and architect External Reference on 3D printed air purifying vases. This is one of a number of new ceramic and polymer design objects that are more than functional incorporating design, functionality as a vase or lamp as well as another functionality such as passive cooling or air purification.

Studio RAP has made 3000 3D printed algorithmically designed tiles measuring 40 by 30 centimeters. Just like Oliver van Herpt did years ago with ceramics for buildings. The studio hopes to develop a complete workflow to do this more often.

Lumika tried and failed to collect waste and turn it into filament for 3D Printed lamps. They failed and now use Refill filament in Malaysia to make lamps.

Braskem spin out Xtellar has brought to market bio based EVA pellets for large format Additive. The 89 A Shore pellets are made from sugar cane and will work with 3D Systems´ Titan and other systems.

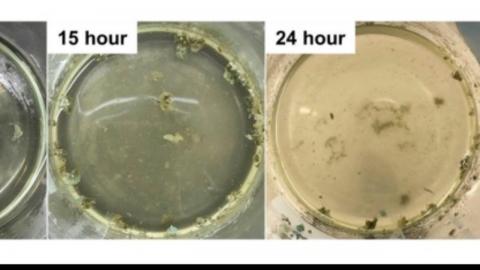

NTU Singapore together with Panasonic have developed a multi material multi-wavelength laser based 3D printer that is capable of engendering different chemical and thermal reactions in polyimide and graphene oxide to turn them into a porous conductive graphene. This lightweight material can be printed on polymer, gold and textiles to make flexible circuits, wearables, sensors and more.

Schaeffler Group is a $13.9 billion industrial conglomerate. A part of it, Schaeffler Special Machinery, has released a multi material 3D printer capable of printing ceramics and metals. Details are scarce but the system could be used for batteries, engines or complex devices that showcase advanced integration and functionality.