3D Printing News Unpeeled: Real Time Keyhole Detection and 21,000 mm/s2

Description

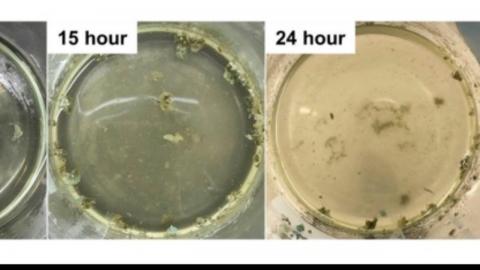

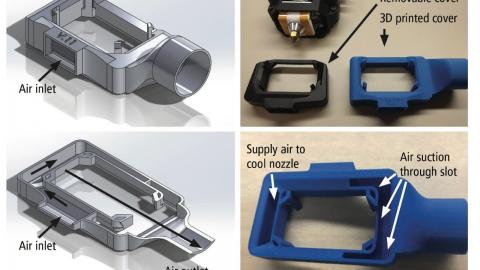

Today we learn of Real time defect recognition in powder bed fusion using machine vision. The research by Tao Sun of the University of Virginia means that voids in models that can cause porosity or failed parts can now be detected in real time and mitigated. We also learn of a new consumer 3D printer with a movement speed of 21,000 millimeter per second squared, a 3D print speed of 600 mm/s, linear rails, silent operation, AI based closed loop monitoring, real time fault mitigation, low vibration and good accuracy as well as printing six colors simultaneously. The printer is an upside down FDM design meaning that most parts are in the base of the printer and the print head prints upside down. This has been shown in research and experimentation but not really in commercial systems. It could mitigate vibration and make the printer more stable. The company also claims to have an app that lets you make a video of a part that is automatically turned into a 3D printable scan. There is a lot to be skeptical of here in what is everything and the kitchen sink.